A detailed understanding of the three-dimensional structure as well as the physical properties of the storage formation forms the base for planning and operating a CO2 storage project. Our experts develop a field model, estimate storage capacity and predict the position of the CO2 plume over time.

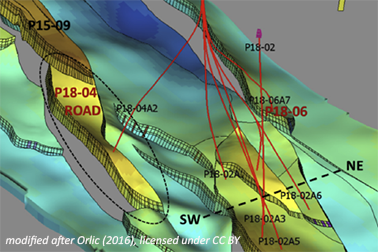

Geological Model: Incorporating all available field and well information our experts build a three-dimensional model of the underground structure and determine all rockphysical parameters relevant for the storage of CO2. This models forms the base for estimating the storage capacity of the site and for the technical planning of the storage project.

Geomechanical Model: To understand and mitigate geomechanical risks it is essential to use all available information to build a model of the stress field in and around the storage formation before the injection start. If the storage site is a previous oil and gas production field also the evolution of the geomechanical situation with hydrocarbon production will be assessed as it has an impact on the geomechanical during injection of CO2.

Dynamic Simulations: Numerical reservoir flow simulations will be carried out to predict the movement of the injected CO2 with time. If oil and gas production data are available, they are used for calibration of the numerical simulations.

Smart Proxy Model: Numerical simulations are time and cost intensive. Thus, a smart proxy model is developed based on a limited number of numerical simulation runs. This smart proxy model can be used in the field monitoring to replace repeated costly numerical simulations for the simulation of the plume position.